[Tested] Industry Nine A35 Mountain Stem

A few months back Industry Nine fired out an A35 stem for testing. As t heir “all mountain” stem, it is also available in a 31.8mm clamp, and in both standards there are an array of colors and even color combinations to choose from with mix and match options for the body and faceplate. For the most part, the lengths are on the shorter side as the stem is aimed at modern trail bike geometry, as I9 puts it. Anyhow, here’s a closer look at how the A35 stem has been working out …

Details

- Includes Six High Strength 316 Stainless Steel Custom M5 Bolts

- 180 Degree Wrap

- 100% Domestically Sourced Solid 7075 Machined Aluminum

- Eleven Anodized Color Choices + Color Combinations

- 140 grams – our scale, 40mm length

- Made in the USA

- $ 145.00

The options and spec vary between the two clamp sizes as you can see from the chart above. The shortest available options range slightly due to the inevitably varied amount of potential interference between the handlebar and the steerer tube depending on the bar’s bulge diameter.

While there is a lot of symmetry throughout the stem, it can be flipped up or down for an increase or decrease of 6mm, providing further setup options for your cockpit.

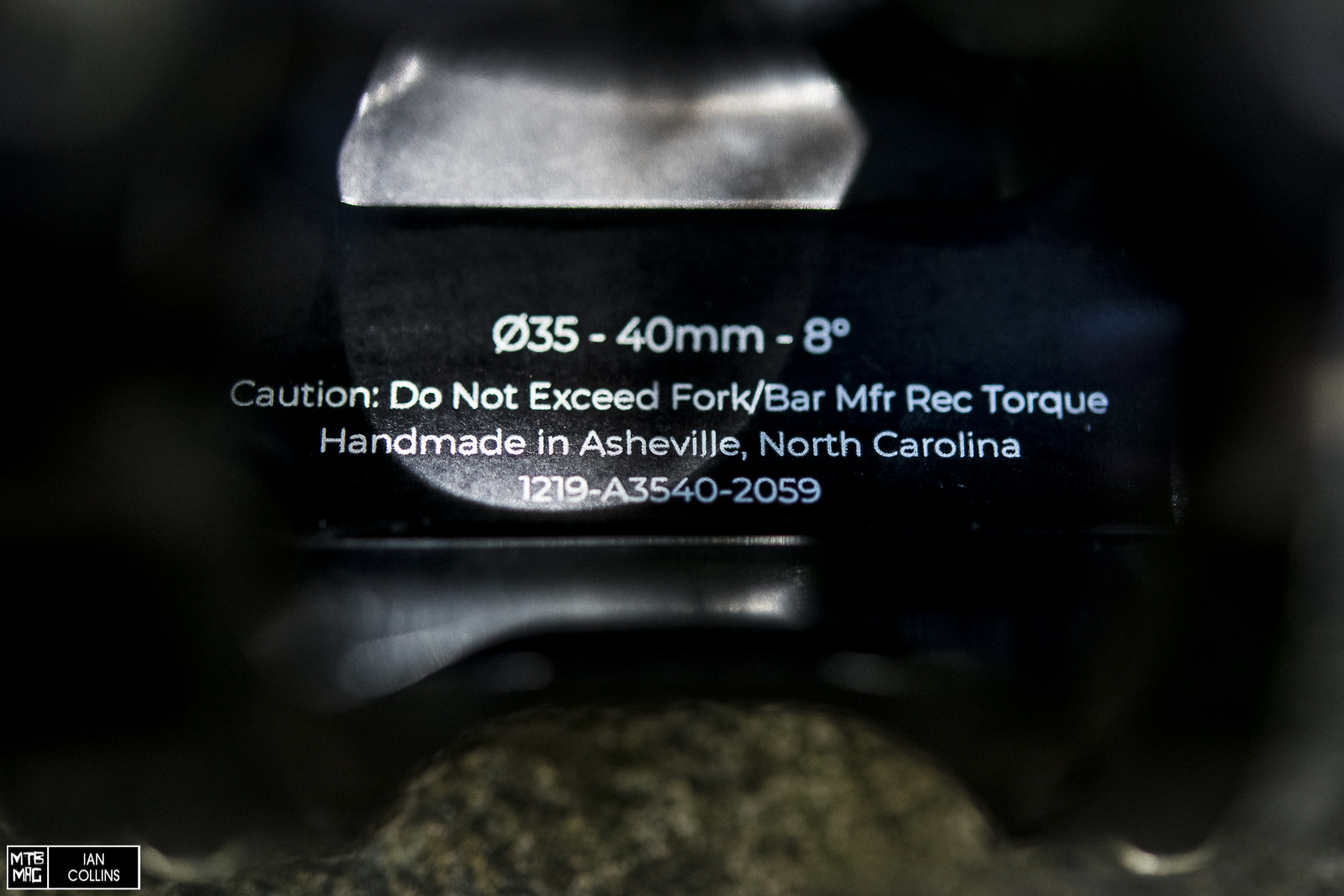

Some instructions are permanently included, etched inside the stem.

Although the right light helps, most will appreciate the stem’s gorgeous lines no matter what.

The “A” series stems get their name from the A-axis of the 5 axis machines that I9 mills them on. Just like their hubs , the stems are made in their Asheville, North Carolina shop.

The separate torque specs for the faceplate and steerer clamp are marked in a clear, classy fashion.

Getting into the function side, both the sides as well as the top and bottom of the steerer clamping surface is rounded off nicely – something your knees may very well appreciate.

A look inside – the relief work is maximized while still retaining an incredibly solid feel.

Another perk – Industry Nine has their hardware custom made to spec. As you can see in the photo above, the stainless steel bolts are chamfered to finish off the A35’s clever shedding of all things hard edged. Brilliant.

In use

As if I wasn’t already giving it away a bit on the lead in, I really like this stem both aesthetically and functionally – clean lines, no hard edges and every detail is flawlessly covered. Starting with the install, Industry Nine won me over immediately with the fact that the stem literally effortlessly drops onto the steerer. Props to I9 for this because if there is one place I don’t appreciate an interference fit, it’s on a stem/steerer tube interface. No one likes wrestling their front end together while their headset bearings are flopping around. Now, a skeptic might wonder that if the inner diameter of the steerer tube clamping surface is a bit on one side of the tolerance, perhaps the stem might not get enough clamping force. Wrong! Although it’s hard to quantify, I’m quite certain that this stem has one of the best bites, if not the best bite that I’ve ever had from a stem in 23+ years of riding mountain bikes. Despite a handful of crashes that would normally very easily rotate many of the stems I’ve ridden, the A35 never moved a millimeter. Over the years, I’ve been fond of Thomson and Renthal stems alike for example, but cannot say the same about either of them as they and many others have twisted easily in minor crashes.

While most stems are reasonably stiff these days, you can usually tell if you are on something that isn’t. I’d be lying to you if I claimed that I can detect subtle difference in ride qualities between most high end stems. With that in mind, the A35 was plenty stiff – it is after all, a solid piece of kit. Even though it’s reasonably light, just by holding it in your hands you immediately feel how sturdy it is. While I’ve recently come to be more open to the idea of torx hardware on stems these days, I found nothing to complain about regarding the hardware. A 4mm allen key interfaced nicely to secure all six of the custom stainless steel screws and the chamfering is a kneesaver. As far as durability and the surface treatment goes, after a long winter with a whole lot of grimy days, hosings and scrubbings, the anodizing is holding up nicely with only very faint scratches coming through and no discoloration whatsoever. Speaking of colors – there are 11 options and the ability to mix and match faceplates should you want to go with a louder option than the black finish shown here.

Overall

The A35, and in turn the A318 for that matter, most definitely tick all the boxes – it’s a struggle to come up with a single downside. Yes, at $145 it’s a bit on the pricey side, but it is made in the US. Better still, it backs up the price with its features and functionality – low stack height, smart hardware, smooth edges throughout, incredibly good bite and just the right amount (+/- 6mm) of adjustability in height. If you’re a utilitarian on a budget, perhaps you won’t feel the need to plop down that much dough, but if you’re an aesthete with a penchant for long game investments, you likely won’t hesitate as the clean lines, classy graphics and strong finish will woo you. I’ve got a new dream build coming down the pipe in a few days, and one of these stems will most certainly be going on that bike. All in all, the A35 is a stunner.

The post [Tested] Industry Nine A35 Mountain Stem appeared first on MTB-MAG.COM.