Formula Disc Brakes Factory Visit

[ad3]

Everyone needs to be able to brake when riding their bikes, thus brakes are a key component. Along with other players, Formula is present in the brake market as a small company that has a solid position, with some big name athletes running their brakes on the World Cup circuit. Their expansion into suspension forks a few years ago helped to cement them as a respected brand, based in Prato central Italy.

We visited Formula’s production facility recently to get a behind the scenes look at how they develop and produce their range of products. We were given a tour of the factory and saw how it happens first-hand.

The headquarter is location in the mountains near Prato.

Formula keeps things simple like their entrance hall, making brakes and forks, their base is simple and they live by their products, not by huge marketing campaigns.

We started our tour at the boss’s office, then the board room.

The pride and joy in the board room is a rather snazzy coffee machine, don’t forget coffee is the life blood of creative thinking in Italy.

The two brothers, Giacomo and Francesco Becocci are sons of the founding owner, they now run the day to day details of Formula – a family run company.

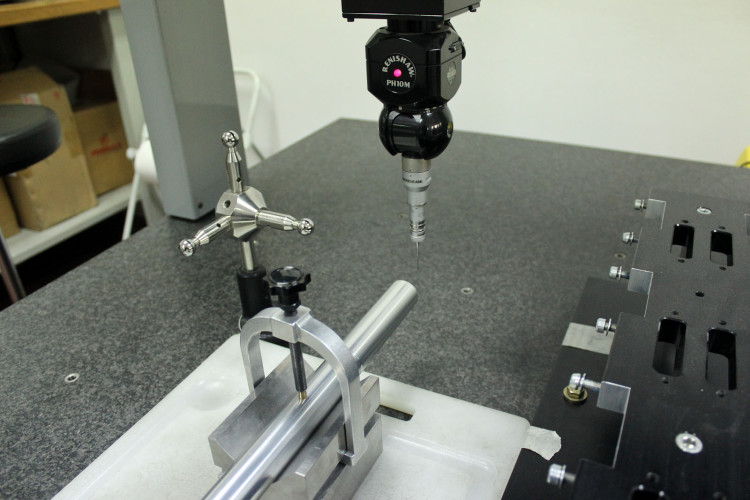

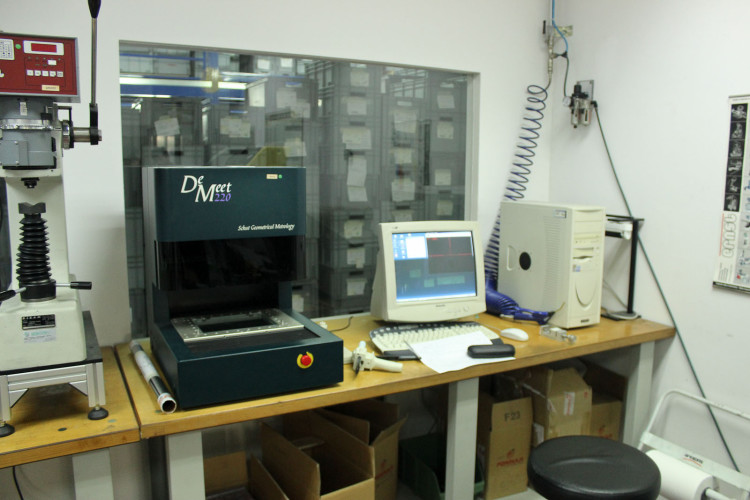

Next stop on our tour was material testing, each and every material Formula uses undergoes quality control testing.

Here, aluminium tubes are checked for consistency and durability.

One of the testing machines running over a tube.

Right next to the testing location is their brake assembly line.

These machines are used for bleeding brakes precisely in accurately cut hose lengths.

Calipers being mounted.

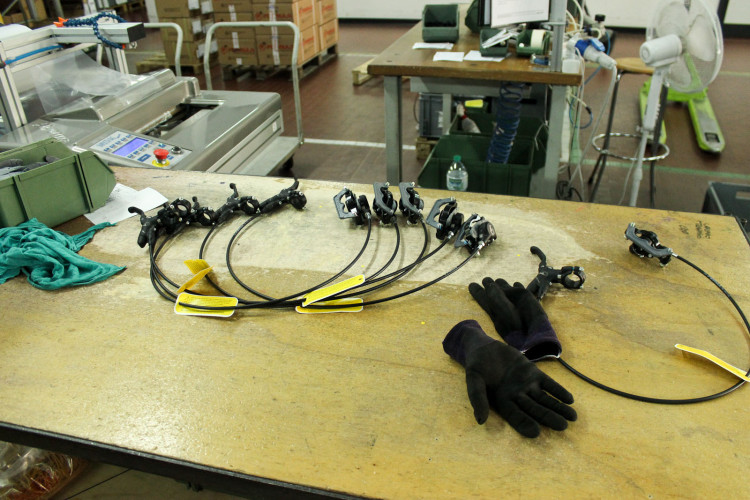

Some completed brake units.

Wandering around, you come across an AIM bike from the 60’s, which is where Formula started before Japanese bikes took over the world.

This man Giancarlo Gestri is responsible for the production machines, building every last one of them, which are all custom built.

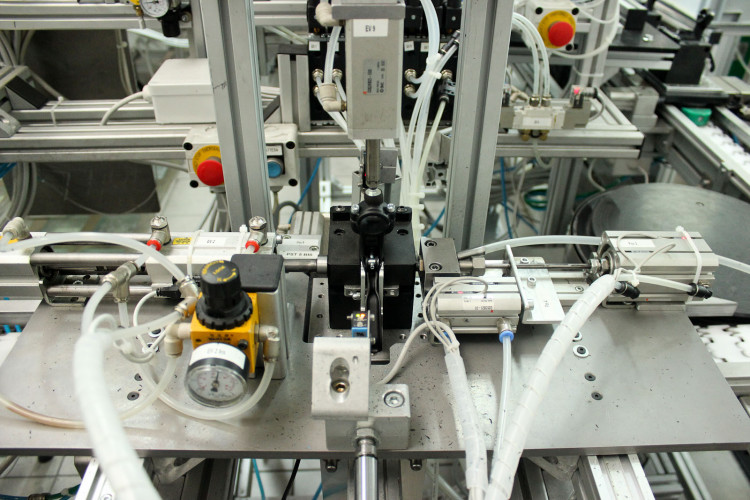

One of his custom built machines is for assembling brake levers.

Here pins are fed into the machine.

The pins are then pressed into the brake handles.

On another line nearby, suspension components are put together.

This machine is for bleeding the damper cartridges.

Thats a lot of dampers, a sensitive component. It’s good to know they are all hand built and checked.

Forks are all hand built and checked before being packed and shipped. Quality control is top notch.

The finished final customer product is stacked high. Thats a lot of brakes.

A batch of forks ready to go, each tested and functioning.

One of Formula’s customer types are OEM bike makers. Here we have brakes ready for mounting.

Brakes are sensitive during mounting, Formula makes sure it supplies all bike manfacturers with the correct hose length.

A hose length trimming machine.

Brake parts for cable cutting and mounting.

We were shown how Formula has spent a lot of time making sure their brakes arrive in the hands of third parties in perfect working order with no air. To do this they have created a bleed free quick cable connect system.

The cables can be disconnected and remounted, with no risk of air entering the system. Formula noted that many bike makers appreciate the ability to thread the cables through internal routing without having to re-bleed the system.

One company asked for some custom colour brake parts.

Stacks of brake calipers ready to be anodised.

We didn’t see much of their latest disc production, just lots of milled components.

Formula have one very large CNC machine for their brake components which has multiple palettes loaded and ready to go.

The raw materials are fairly simple, drawn metal rods that must meet certain quality specifications.

Waste products are recycled.

Whilst wandering around we did get to see a few secret bits, this is a part of a hub component in prototype phase.

Formula are proud of this little gem, their new entry level brake that has enjoyed some world cup time and was definitely up to the challenge, soon to be presented and on the market in 2016/2017. So far it’s secret and only visible here for the first time.

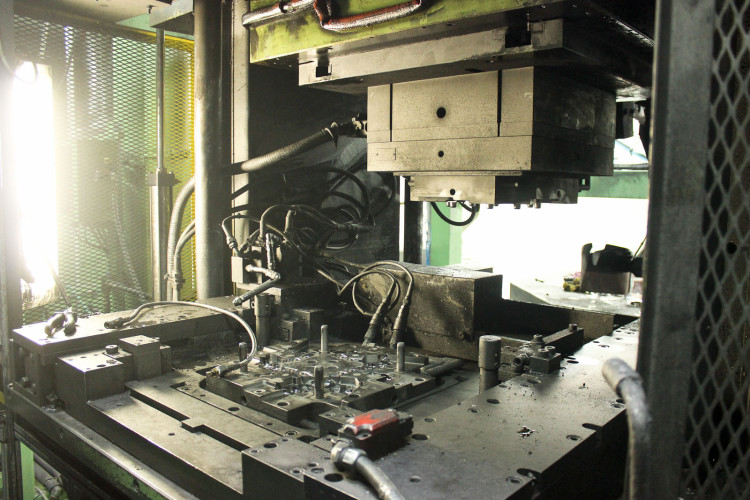

This machine is Formula’s forge. All metal forgings are done on site.

The bed of this part of the machine is where hot metal is injected.

These are the furnaces that melt the metal, and surprisingly they run on electricity.

We are shown their machines for removing burrs and blemishes from the forged components. They are basically giant mixing tubs.

The metal components are placed in here and tumbled with the smooth stone chips to make sure they are completely smooth.

They then pass through this machine where they are washed. The average life of each machine is around 10 years.

Once produced, Formula go to great lengths to test their products. Here is a line up of their forks which have been “tested”.

Although not likely to happen on the trail, this is one test that fork legs undergo.

Luca shows us how they test suspension deflection.

Later on our tour we get to go into Otto’s empire… Otto is the Formula World Cup Mechanic that has been providing support for athletes over the years.

Otto in his environment.

Otto is the man who looks after customer servicing and makes sure his knowledge is felt directly by the end user.

Old school Minnaar. He was running Formula brakes back in the day on the Honda Downhill team.

This is how far Otto goes back! 1981 bike racing.

Love for Otto from the legend CG!

[ad45]

The post Formula Disc Brakes Factory Visit appeared first on MTB-MAG.COM.