TRed Innovates 3D-printed Alloy X23 Track Bike Prototype with Rider-Customized Aero

TRed bikes take custom aerodynamics to a new rider-individualized level in their latest X23 Swanigami track bike prototype – inspired by such iconic track developments like the Lotus 108, Pinarello Espada, and Graeme Obree’s controversial “Old Faithful”. Combining years of biometric 3D scanning of riders with the latest additive manufacturing technologies, TRed’s X2_ track bike prototype development project aims to make next-level aerodynamic performance tailored individually to each cyclist more attainable…

TRed X23 Swanigami 3D-printed alloy track bike prototype

We’ve been watching TRed’s custom track bike development progress rapidly over the past decade. What started with premium custom-fit steel and aluminum track bikes that drew attention – and accolades – at NAHBS in the US, has developed into something much more race-focused.

The last evolution we had caught up with was the Peregrine-inspired Falcon, which effectively was the starting point for this X2_ prototype development project. Now this X23 is the latest iteration, but according to TRed it’s continuing to adapt through racer feedback, computer simulation, wind tunnel development, and real race testing on the track.

How does rider-centric aerodynamics make the bike faster?

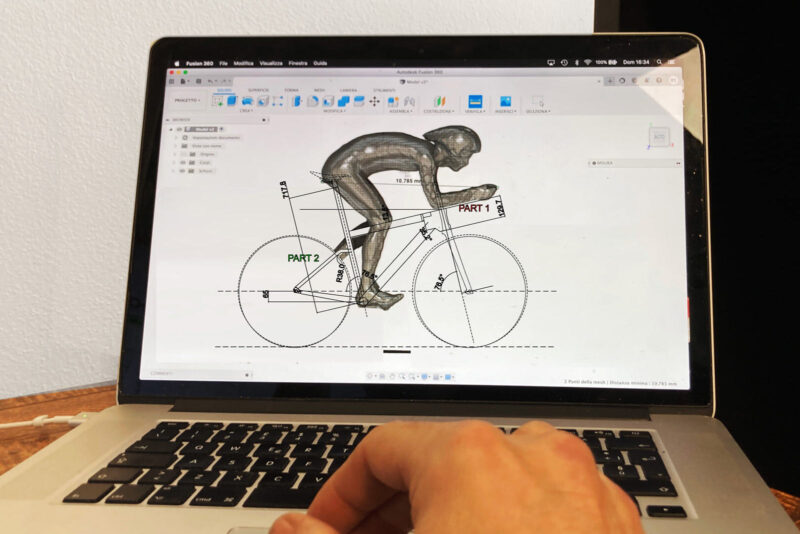

Leveraging their custom fitting process that employs a unique 3D-scanning of the rider since 2016, TRed leaned on the fact that a well-fitting track bike where the rider can maintain their optimal aerodynamic position for longer is often times the fastest track bike.

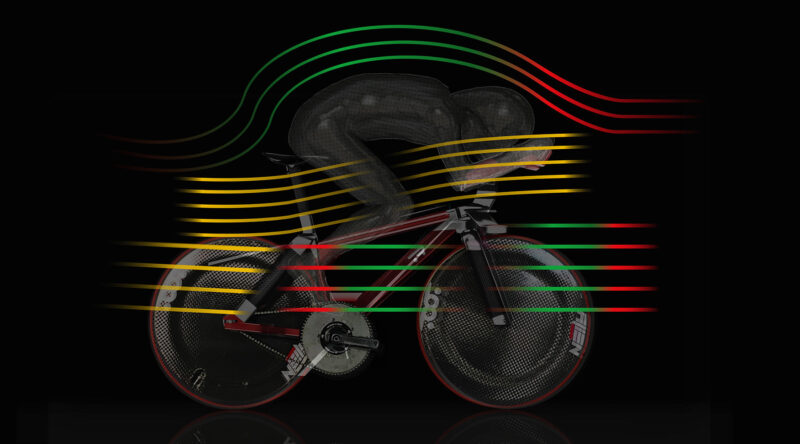

The rider makes up such a significant portion of the aerodynamic drag of a track bike, TRed and their factory TOOT Racing team looked at how to make the rider faster first, then how to use that slippery aero rider to make the bike faster too.

They call the process “digital twins” as they model the virtual rider on the bike in the computer, then compare the data with the actual measurements of the same rider and real bike mocked up in the wind tunnel.

This allows them to better reconcile the complex and dynamic relationship that is typically difficult to accurately estimate in CFD simulation.

TRed says they looked to the history of innovations on the track for inspiration, where of course they came upon the narrow, forward positions of Graeme Obree on his unique hyperbikes. They also note how many of the most iconic track bikes have done away with the toptube in an effort to reduce drag.

The result of dynamic biometric optimization – first modeled virtually, then refined in the wind tunnel – is a more aerodynamic rider position. With that established, TRed creates the most aerodynamic bike design under the rider – figuring on the real airflow character coming off the rider’s forearms, pushed down off their chest, and flowing off the rising & falling motion of the racer’s legs while pedaling.

While religiously reducing frontal is often the primary concern in reducing track bike drag, TRed’s rider-centric aerodynamic approach, for example necessitated moving the frame tubes away from the pressure wave coming of the rider’s chest and directing airflow wider off the fork to relive air pressure, and ultimately reduce total aero drag.

The true bodywork of the binomial bicycle/cyclist is the athlete: he is the engine and the “fairing” at the same time and therefore it must be designed as a technical part: it must perform at its best from a mechanical point of view and interact better with the components to optimize aerodynamics.

– Romolo Stanco, T°Red founder and Chief Technical Officer of TOOT Racing

UCI approval to race, and registered for the Olympics

Now, TRed & Toot are working within the confines of more restrictive current UCI technical design regulations, but they are pushing the envelope with features like the severely sloping toptube, deep airfoil tube shapes, tubing junction webs, and integrated cockpit.

TRed assures us that the X23 Swanigami frame does comply with UCI rules, and will be UCI-approved in time for the Argentina national team and their rider Facundo Lezica to compete on the bike at the upcoming UCI World Championship in Glasgow this summer, and registered to race the Paris 2024 Olympics next summer. Some components like the custom-made handlebar & aero extensions have already been Olympic-approved and raced in the 2023 Nations Cup.

A 3D-printed aluminum bike in a sea of carbon?

A big benefit here is that weight often isn’t such a defining factor on the track, so TRed could work with various metals to deliver the more important stiffness characteristics necessary for super powerful track racers to get the most out of their bike. Metal tube shaping had been a limiting factor to optimized aerodynamics in years past. But just like we saw with Pinarello’s 3D-printed Hour Record bike, modern additive manufacturing now often means that a metal bike can be just as quick, or even quicker than a carbon bike, without the long development time to create and adjust expensive molds.

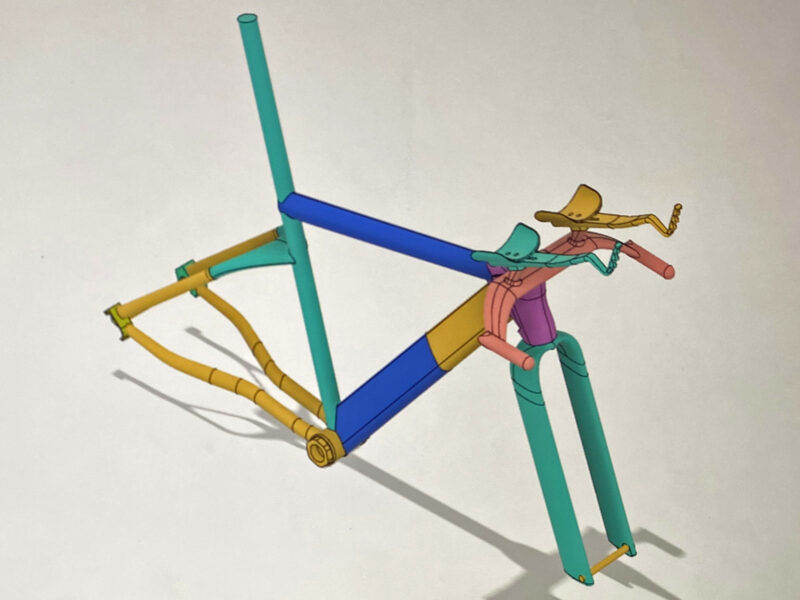

Ultimately, many elements of the TRed X23 are created in an R&D partnership with the University of Pavia’s 3D PROTOLAB, then combined with other forged or CNC-machined alloy parts, and even some composite elements.

The additive-manufactured X23 frame is primarily constructed of 3D-printed aerospace-grade Scalmalloy scandium aluminum alloy, thanks to its high strength:weight ratio. (Still very much hidden here in razzle dazzle camo.) Other parts of the custom track bike are also 3D-printed in titanium or in steel, like the super-narrow Asheeta 3D handlebar.

Thanks to the use of 3D-printed metals from frame to cockpit components (and polymer mockups during prototyping), TRed says they can turn around new prototypes in record time, at costs that bring the fully-customized process into reach for smaller teams and national federations.

What’s next for the 3D-printed X23 Swanigami & TRed’s X2_ project?

Officially the X23 is the current iteration of the ongoing TRed X2_ track development project – TRed even calls it a “first stage”, still ‘in testing’ on the track. While it is ready for the Argentinian team to race internationally, TRed is still moving forward with optimizing their iterative aerodynamic designs.

But even though it is still a work in progress, it is an open project, and meant to be both accessible and more sustainable due to its use of resilient, recyclable metal materials. TRed are always interested in new riders and new teams looking to work together on their motorsports-inspired research, race, and development projects.

TRedBikes.com & TootEngineering.com

The post TRed Innovates 3D-printed Alloy X23 Track Bike Prototype with Rider-Customized Aero appeared first on Bikerumor.